Greenboy3D™ PC/ABS GF20 Pellets

PC/ABS GF20 Pellets – High-Performance Printing Made Affordable

Take your 3D printing to the next level with PC/ABS GF20 Pellets, a high-performance material reinforced with 20% glass fiber (GF) for exceptional strength, stiffness, and durability. This advanced composite offers increased impact resistance and heat resistance of up to 120°C, making it ideal for demanding applications. Compared to traditional PC/ABS GF or CF filaments, which can cost $50 or more per kilogram, these pellets provide the same performance at a significantly lower cost.

Cost Savings Without Sacrificing Quality

High-performance materials like PC/ABS GF or CF filaments are essential for industrial-grade projects, but their high price often limits their use. With PC/ABS GF20 Pellets, you can achieve superior mechanical properties and thermal resistance while saving up to 85% on your 3D printing costs.

For example:

- 5kg of PC/ABS GF or CF filament could cost $250 or more.

- Using pellets allows you to access the same performance for a fraction of the cost, making it perfect for budget-conscious makers and professionals alike.

Key Features:

- Practical Packaging: Packaged in 5kg resealable ziplock bags, these pellets stay dry and are easy to access, ensuring convenience and reliability for your projects.

- Direct 3D Printing: Optimized for direct use with my Greenboy3D Pellet Extruder, these pellets deliver smooth, consistent printing results with superior mechanical performance.

- High-Performance Material: PC/ABS GF20 combines the toughness of ABS, the heat resistance of PC, and the reinforcement of 20% glass fiber, providing increased stiffness and impact resistance along with thermal stability up to 120°C.

- Exceptional Versatility: Ideal for functional parts in automotive, electronics, tooling, and other applications requiring high impact resistance and thermal stability.

Why Choose PC/ABS GF20 Pellets?

PC/ABS GF20 is the material of choice for demanding projects that require a balance of strength, durability, and heat resistance. By choosing these pellets, you can print advanced components without the high cost of traditional filaments, making it easier than ever to tackle high-performance applications.

Order your PC/ABS GF20 Pellets today and experience the strength, heat resistance, and cost savings only possible with the Greenboy3D Pellet Extruder!

Technical Datasheet

Greenboy Pellet-Extruder explained in more depth

Learn more about my Pellet Extruder, whether you can use it on YOUR 3D Printer aswell and some other topics.

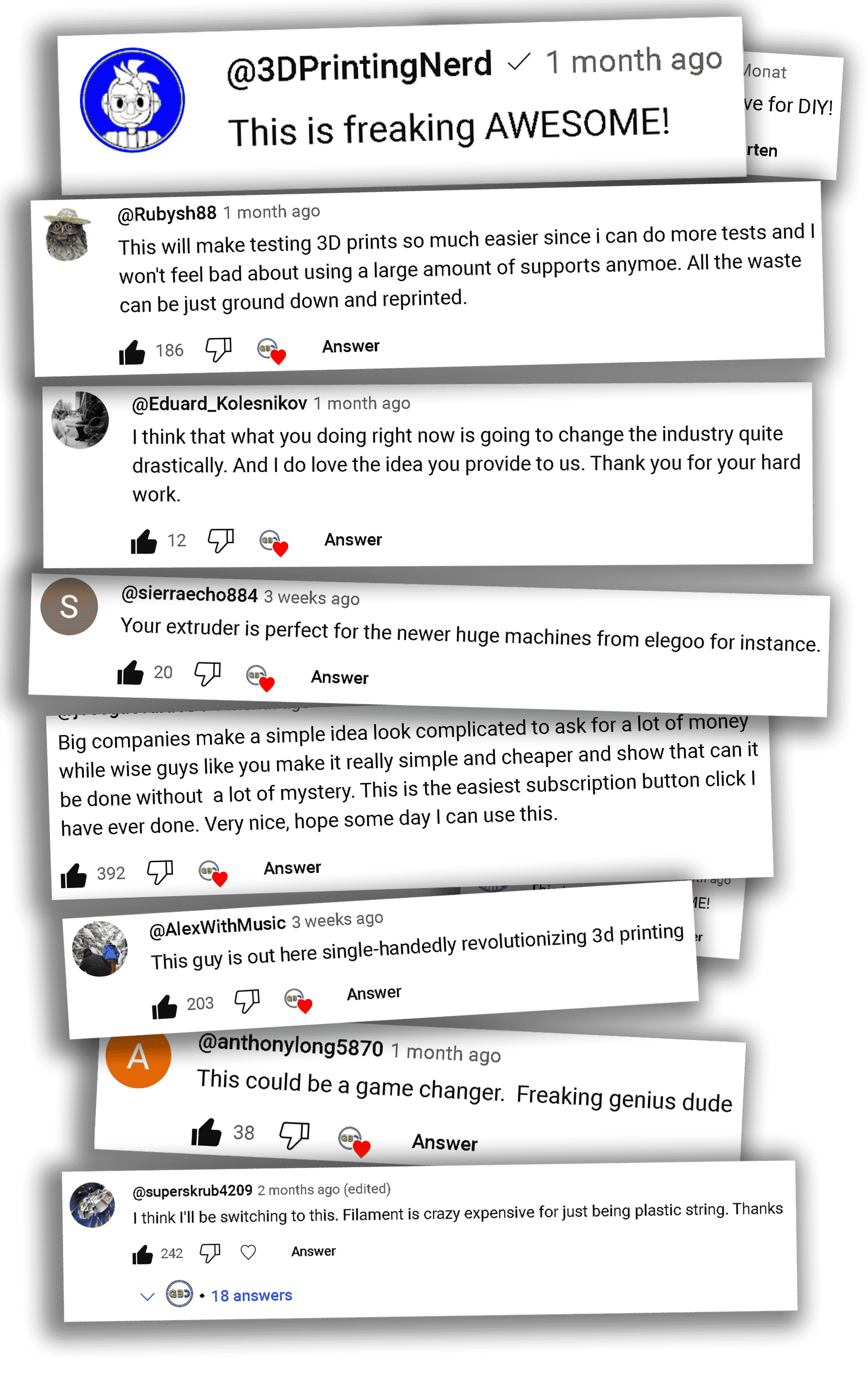

What people say about Greenboy3D

Save up to 90% on your 3D printing costs

Every filament and piece of plastic you’ve seen started as plastic pellets. While a spool of filament (1kg) costs $20 – $60, the same amount in pellets is just $3 – $8.

You can save up to 90% on printing costs by upgrading your 3D printer with my universal Pellet-Extruder-Printhead, allowing you to print directly with pellets.

More about PelletsRecycle plastic waste into anything

With a Greenboy Pellet-Extruder-Printhead, you can recycle any plastic waste—like empty filament spools, water bottles, yogurt cups, and failed prints—into new objects.

Simply shred the plastic into pieces smaller than 0.2 inches (5 mm) and 3D print with them again. This method offers a sustainable future, turning plastic waste into new, purposeful items instead of discarding it.

More about Recyling3D print with chocolate, sugar or anything else melting in the range: Ambient – 330 C°

It’s true! You can 3D print chocolate with my Pellet-Extruder-Printhead. Though not originally intended, any meltable material smaller than 0.2 inches (5 mm) works fine.

For food safety, most parts in contact with food are stainless steel. If strict food safety is a priority, you can spray the rest of the extruder with food-grade silicone spray or use other methods…

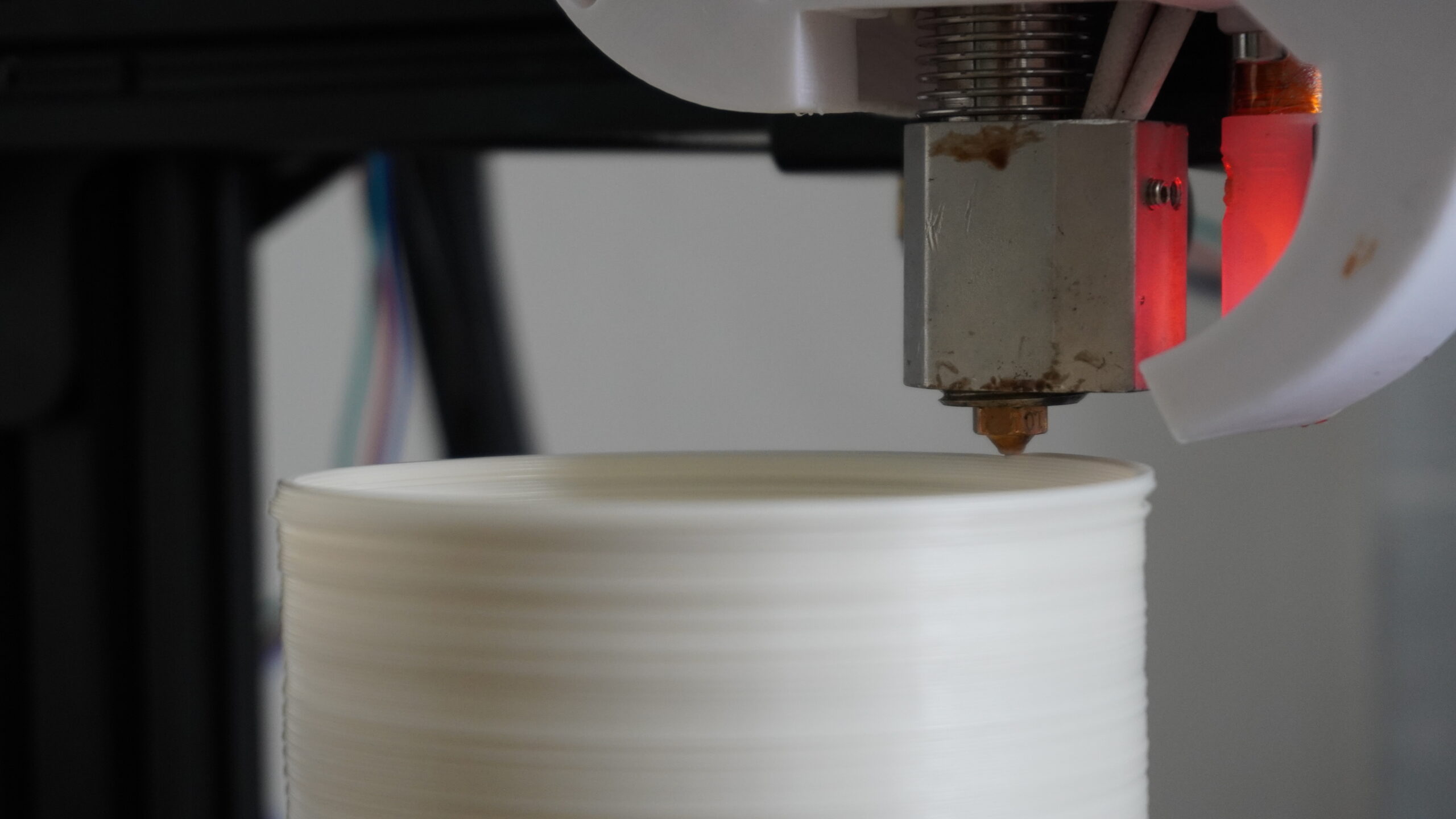

More about non-plastic materialsSome actual 3D printing footage

(Normal Plastic) - PLA (220 C°)

(Elastic Plastic) - TPU 5A Shore - (240 C°)

Advantages of my Greenboy Pellet Extruder

Extremely Universal

Thanks to the concept of using 3D printable adapters, you can use this extruder on almost any 3D Printer

Lightweight ~ 700 grams

Through innovative thinking I managed to replace a lot of metals parts with 3D printable plastic parts and this significantly reduced the weight

Most inexpensive Pellet Extruder

Through innovative thinking and some new approaches I managed to reduce the production costs, which allows to have a lower price

Easy to use

Thanks to some special features, it is quite easy to use this pellet extruder, because many problems conventional 3D Pellet Extruders have like unloading pellets have been solved

125 – 200g/h Flowrate

Depending on the material you use, its size, shape and viscosity, you can expect to achieve a maximum flowrate between 125 – 200 grams per hour with a 1mm nozzle. Using a bigger or smaller nozzle does influence the maximum flowrate capabilities…

Technical Information

Parameter

Net Extruder Weight:

Max. Temperature:

Max Environment Temp.:

Flow Rate:

Nozzle Sizes:

Nozzle Compatibility:

Voltage:

Compatible Pellet Size:

Specification

~700g

330°C (up to 450°C)*

Up to 80°C

125 – 200g/h Max Flow

0,4mm up to 2,5mm

Standard M6 Nozzles

24V

Smaller than 5mm

*Upgradeable to 420°C

**Max Temperature is also determined by the heat resistance of the plastic you choose for the 3D printed Extruder parts. For example: Extruder parts out of PLA can withstand Extruder Temperatures up to 300°C but not beyond

Control color and transparency level of your prints

Instead of buying pre-colored filament and being limited to that color and spool, you can buy a bag of plastic pellets and some color pigments, sprays or paint.

Now you can universally print with any color you desire at a fraction of the filament cost simply by mixing a specific amount of pellets with a chosen color, which will result in, for example, 1/2 pounds of blue-colored PLA for one of your specific projects.

Depending on the concentration of colors in your pellets, you can achieve everything in the range of transparent prints with a little color and up to full-solid color prints. Another cool thing is mixing or stacking different batches of colored pellets on top of each other. This will give amazing gradient colors to your 3D prints, as you can see in the image nearby.

Step 1

Apply a Color on Pellets

Step 2

Mix everything by shaking

Step 3

Let everything dry out

+ you can add custom additives to your pellets

“Additives” is a word for substances that improve or change the properties of plastics. By using the same methods for coloring your pellets, you can add, for example, “glow in the dark” substances to your pellets to get cool-looking prints that glow at night. But that is just one out of many possibilities you can try out…

The Person behind Greenboy3D

Hi, my name is Kristian, I’m 23 years old and my mission is to make Pellet 3D Printing globally less expensive and more accessible…

Back in the year 2022 I was very frustrated with the cost of 3D Printing and especially the waste it produces. At that time, I knew that 3D printing directly with Plastic Pellets & Shredded waste is possible.

But there were no low cost options, and it also seemed like as if the 3D printing industry doesn’t have much interest in developing this technology, despite its great potential.

This frustrated me even more, so I decided to develop my own Pellet Extruder without having any knowledge about engineering at that time…

For more than 2 years I struggled, worked extremely hard and spent most of my income on the development while living under poor conditions…

No matter how hard times were, I never gave up and this why Greenboy3D exists today…

ME working at UPS from 4 AM to 8 AM for 2.5 years to finance Research & Development costs